Application of rubber anti-aging agent in the cable industry

Common high-temperature cables are wrapped with a layer of “rubber protective layer”. When such a protective layer is destroyed, the inside of the high-temperature cable will be damaged and cannot be used anymore, so the manufacturer will prevent the outer rubber protective layer from aging. Treatment, this process involves the anti-aging agent.

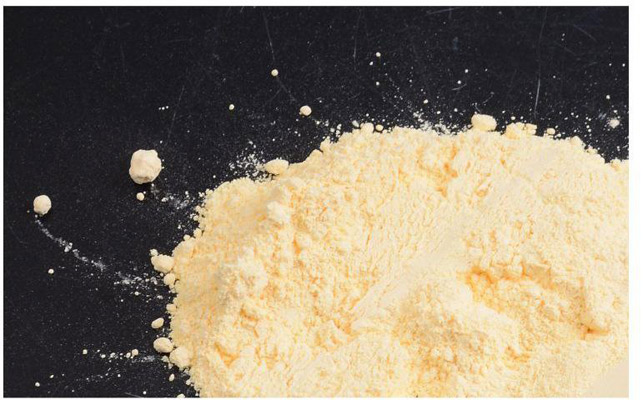

First: due to the different characteristics of each type of antioxidant, and the aging properties of different rubber formulations are different. Therefore, the most effective anti-aging agent for a certain rubber material may be ineffective or even harmful to another rubber material. Therefore, the selection of anti-aging agents must be considered in accordance with the aging properties of various rubber materials, anti-aging requirements and the characteristics of various anti-aging agents.

Second: When an anti-aging agent is difficult to meet the requirements, two or more anti-aging agents should be used together to create a coordination effect to ensure anti-aging effect.

Third: Some anti-aging agents have a coloring effect and pollution on the rubber. In general, phenolic antioxidants have poor protection, but are not contaminated or have little contamination. The amine anti-aging agent with higher protection effect will cause rubber pollution and serious discoloration. These contradictions should be considered when they are selected.

Fourth: the amount of anti-aging agent can not exceed the solubility in rubber to prevent frosting, pollution of rubber surface quality

Fifth: the amine anti-aging agent has an adverse effect on the rubber coke; the phenolic anti-aging agent can delay the vulcanization, and should be noted when selecting.

The treatment of the rubber protective layer by the anti-aging agent also needs to be taken seriously as an important protection measure for the high-temperature cable. With a solid protective shield, the service life of the high-temperature cable can be further ensured, and the erosion of various hazards can be resisted.

English

English